Oil in Water Real Time Monitoring

Having monitoring systems, simple to install and maintain which report in real time the presence of hydrocarbons in surface or sea water, allows to avoid or minimize environmental damage or damaging to the plants which are using the water.

Here is an example.

DESALINATION PLANTS

PROBLEM

For desalination plants, crude oil spills pose a serious threat. The sea water, fed to the system, if polluted, damages the pipes, reduces the performance of the exchange surfaces of the osmosis plants and pollutes the production of fresh water particularly when, due to the temperatures reached by the exchangers, they trigger distillation processes.

For a desalination plant, the damage caused by hydrocarbon pollution can be countered by circulating, inside the units, which carried out a cleaning action.

However, it happens that in osmosis plants, the membranes, despite cleaning, suffer serious damage from hydrocarbon pollution which significantly compromises their operation.

The location and geography of the plants are an important factor in assessing the risk level of oil pollution. Busy shipping routes nearby, ports or refineries significantly increase the risk of spills, routine bunkering and ballast water discharge are a regular source of contamination.

Let's consider the examples described below

The first is a desalination and energy production plant that uses coastal waters in the UAE. The second one is located on the coast of Malaysia.

Both require effective monitoring of the incoming water in order to ensure that no oil pollution gets inside the process plants

SOLUTION

Adopting a continuous monitoring system at the taking points is essential to increase the effectiveness of existing systems; providing active and passive protection to the plant

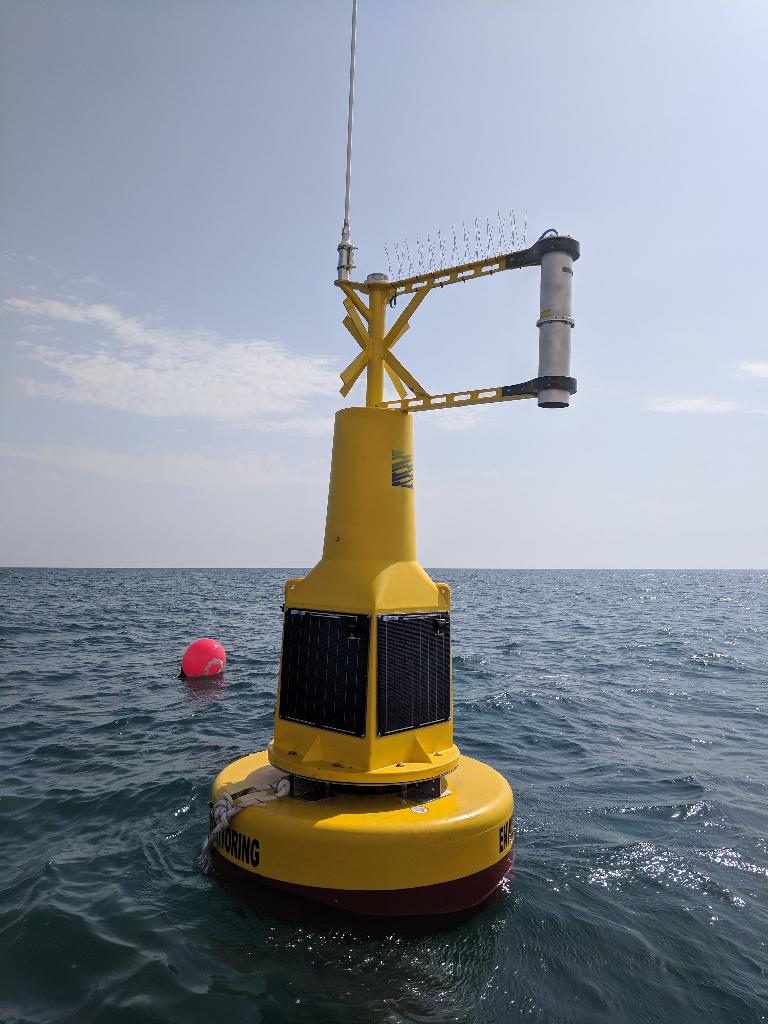

The installation of a network of ROW hydrocarbon presence sensors, (Remote Oil Watcher), in the the water outlets surrounding area, allows the preventive detection of potential threats. This gives to the operator the right time to take a decision in order to contain the pollution coming.

Buoy-based ROW sensors are perfect for this application: they are resistant to waves and storms, operate reliably 24/7 and also allow for offshore.

For ground installations, the alarm of a spill detected by ROW LDI, nearby the plant, gives the time to stop pumping of the water inlet until the problem is solved and makes it possible to start cleaning operations allowing a fast resuming of the operations.