Description

ASTM D2892 Distillation from 2L up to 100L.

D2892 TBP Distillation for Crude Oil, Petroleum Products, Chemicals, Bio fuels, Bio Oils, Ethanol Etc.

FULLY AUTOMATIC ASTM D2892 MVD UNIT.

- No operator intervention from start to FBP 375°/450°C AET

- Up to 250 TBP analysis per year

- Easy operation in local mode and more versatile use in remote supervisor mode.

Fully automatic distillation unit in accordance with ASTM 2892 method for the distillation of crude oils or cuts with automatic procedure from debutanisation to reduced pressure without any intervention from the operator.

The unit includes a D2892 column with Multiknit packing and a stainless steel boiling flask, with capacity 2 To 22L .

L’unità include una colonna conforme al metodo ASTMD2892 con riempimento Multiknit e un pallone di carico in acciaio inox, con capacità da 2 a 22 litri.

Special column and flask size on request.

This unit can carry out all types of discontinuous distillation of chemical and organic components for boiling temperatures up to 200°C/392°F under atmospheric pressure and also at vacuum down to 0.5 mmHg which corresponds to an atmospheric equivalent temperature (AET) of 400-452°C/752-845°F.

The complete TBP D2892 distillation can be performed without human intervention from the debutanisation stage to the Final boiling point within about 15 to 18 hours.

ll the different sequences are chained automatically up to the point where the unit is ready for the operator to retrieve the fractions prepared by temperature and/or % volume set points.

The collecting fraction receivers are automatically weighed and capped with a stopper.

These receivers can also be retrieved at any moment during the distillation.

The MVD process cabinet is a closed cabinet with safety doors for easy access.

MAIN BENEFITS

- Fully automatic from loading the sample crude to FBP 375/450 C AET under vacuum.

- Local mode and supervisor mode control.

- Automatic fraction collectors up to 36 receivers per batch. Maximum 72 fractions.

- High level of safety allowing to run day and night with high throughput of analysis per year.

- up to 250 TBP a year.

- Distillation of any kind of petroleum or petrochemical products or fractions such as gasoline, diesel, kerosene, lubricant etc. But also Bio Fuels and Bio Oils Etc.

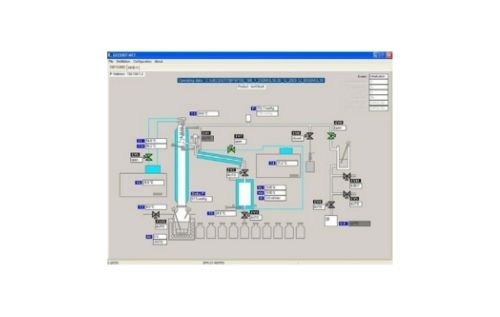

GECDIST Net supervisor SOFTWARE

GECDIST Net supervisor software allows to monitor several distillations from GECIL Process MINIDIST PLUS product line such as TBP, Pot Still and D-1160.

Up to 16 distillation units can be link to one PC supervisor GECDIST Net.